As early as a few decades ago, the United States began the research and extrusion of wood-plastic composites, but due to the immature processing technology, compared with plastics and pure wood products, there are many performance defects, wood plastic composites have not been rapid development.

With the breakthrough of industrial technology level, the new processing technology has greatly improved the performance of wood Plastic composite materials, and the market of wood-plastic products has opened rapidly with the breakthrough of industrial technology level. The new processing technology has greatly improved the performance of wood-plastic composites and opened the market of wood-plastic products rapidly.

1:What is wood plastic ?

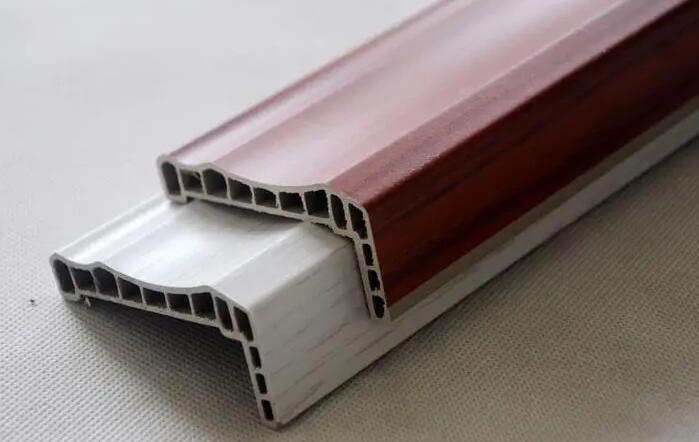

Wood Plastic Composite (WPC) is a new kind of composite material which is flourishing in recent years at home and abroad. It refers to the use of polyethylene, polypropylene and polyvinyl chloride (PVC), instead of the usual resin adhesive, and more than 35% – 70% of wood flour, rice husk, straw and other waste plant fibers mixed into a new wooden material, and then extruded. Molding, injection molding and other plastic processing technology, the production of plates or profiles.

At present, mainly used in building materials, furniture, logistics packaging and other industries. It is called extruded wood plastic composite board that the plastic and wood powder are mixed in a certain proportion and then hot extruded.

Second, where can wood plastic be applied ?

In the garden landscape, wood plastic is an excellent material choice. Because of its strong water resistance, non-perishable, does not require frequent maintenance, wood plastic is widely used in outdoor floors, fences, flower boxes, benches and so on. Whether it is a family garden, public park or tourist attraction, wood plastic can create a natural and harmonious atmosphere, while ensuring a long service life.

Interior decoration is also a major application scenario of wood plastic. Compared with traditional wood, wood plastic is more wear-resistant and scratch-resistant, suitable for wall decoration, ceiling, kickline and so on. Especially in humid environments such as kitchens and bathrooms, wood-plastic performance is far better than ordinary wood, and it will not be deformed or moldy because of humidity changes.

In the construction industry, wood plastic also has a wide range of applications. For example, it can be used as a temporary support material that can be easily recycled after construction is over. In addition, wood plastic can also be made into roof tiles, exterior wall panels and other building materials, both beautiful and durable.

Commercial facilities such as restaurants, cafes, hotels, etc., in order to create a warm and comfortable environment, wood-plastic materials are often used to make tables, chairs, counters, floors, etc. The easy cleaning properties of WPC make the daily maintenance of these sites much simpler.

In transportation, wood plastic also has its place.Seats, floors, ceilings of light rail and buses can all be made of wood-plastic materials.To reduce vehicle weight, improve fuel efficiency, and provide a better passenger experience.

As a new material that integrates the advantages of wood and plastic, WPC has a wide range of applications, whether it is in indoor and outdoor decoration, garden architecture, or in the field of commerce and transportation, WPC can meet people’s diverse needs with its unique performance. In the future, with the continuous progress of production technology and the expansion of application fields, the development prospects of wood plastics are undoubtedly bright.

In the process of promoting and applying WPC, we should fully realize the dual value of environmental protection and economy, And pay attention to maintenance and maintenance during actual use to extend its service life,Maximize its environmental benefits.. At the same time, for the development of the WPC industry, we should also continue to pay attention to its technological progress, market dynamics and relevant policy guidance to ensure that this green material can go further on the road of sustainable development.