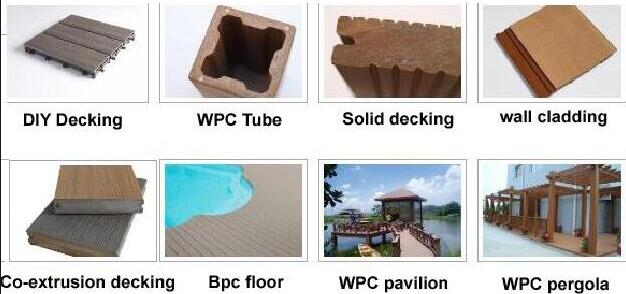

Product Category

- Composite decking (WPC )

- DIY interlocking decking tiles

- Wall Panel(composite Siding)

- WPC | Composite Fencing

- WPC | Composite Railing

- WPC Bench

- WPC dustbin

- WPC Flower Box

- WPC Pergola|Pavillion

- WPC Table

Contact Us

Salesman Name: Nick ,Jean

Tel:+86-572-6076365

whatsapp:0086 18705825615

wechat:3402182830

Skype:Nickwpc88

Email: Admin@hanmingwpc.com

Add:Huzhou City, Zhejiang, CHINA

Follow Us:

- Outdoor WPC decking

Hanming WPC Pergola

WPC Fence

Hanming WPC dustbin

Pontoon composite wood

Terrace WPC decking

Archive for September, 2018

-

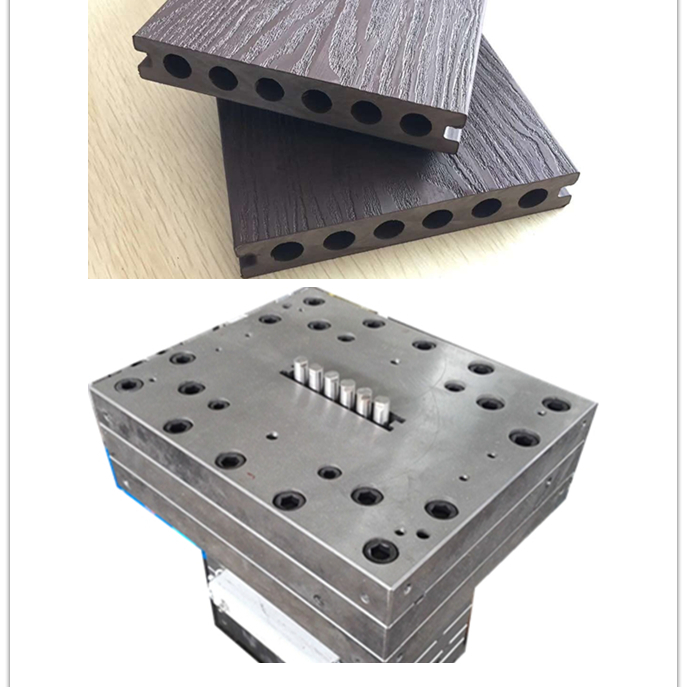

china wpc outdoor flooring moulds supplier

The design of plastic extrusion die extrusion thermoplastic elastomer extrusion die includes the design of geometric parameters (such as wall thickness, reinforcement, radius, hollow and hinge), and the effect of them on the processing and performance of the product should be considered. The general guidelines for extrusion design are listed below. Wall thickness Uniform or nearly uniform section thickness will be easier to process, reduce costs, better error control, better surface finish and more complex shapes. The minimum wall thickness is 0.5 mm (0.02″), while the maximum wall thickness is 9.5 mm (0.375″). A thinner wall thickness is possible, but santoprene8000 thermoplastic elastic system column is needed. The change of wall thickness should be smooth and smooth, and should be as small as possible, because this will help stamping die balance. Reinforcement In the process of wall thickness change, if the thickness change is too intense and too large, problems may occur in the process of balancing the flow field. The thickness of the reinforcement should be 50% of the nominal wall thickness, and the radius should be designed on this basis. Rad radius The sharp changes should be replaced by rounded corners. Extrusion parts have a minimum radius mm(0.007″).0.20 […]

-

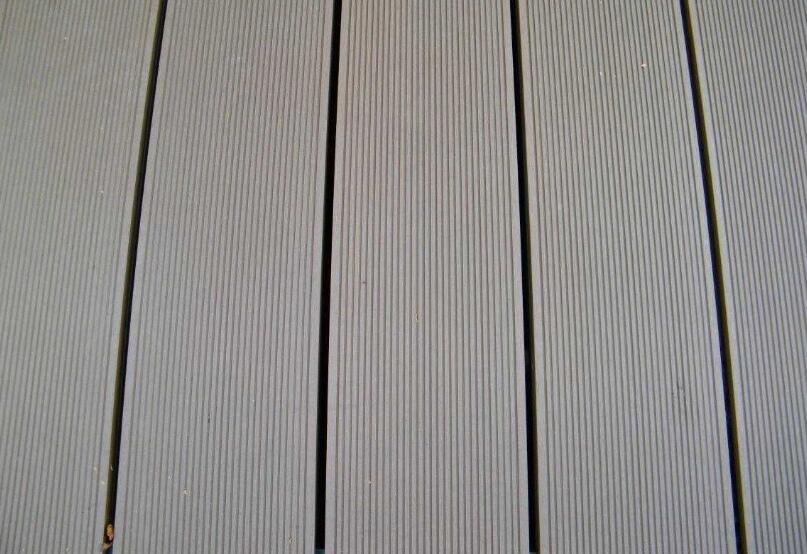

The suggestion for how to choose WPC decking properly

Wood plastic outdoor flooring is a kind of flooring with rapid market increment in recent years. Because of its peculiar texture luster and stable performance, it has been favored by many consumers, but the real understanding of wood-plastic flooring is still not much. Just say, when we buy, the right way to choose and buy, do you know? 1, to see the side of wood-plastic floor: good quality wpc decking side of the smooth, glossy shiny, a sense of oil-run, no small cracks. Poor quality of wood-plastic floor side of the rough, shiny dim, no oil-run feeling, and some poor elongation due to PE cracks. 2, look at the front of composite decking: good quality wood-plastic floor front smooth, glossy shiny, wood powder particles small and uniform size. Poor quality wood-plastic floor front rough, shiny dim, wood powder particles larger, different sizes, uneven distribution. Two kinds of floor put together, the difference is obvious. 3, look at the wood-plastic floor section: good quality wood-plastic floor section texture tight, shiny glossy, small and uniform distribution of wood powder particles. Poor quality of the wood-plastic floor section texture loose, shiny, wood powder particles larger, different sizes, uneven distribution, and obviously see the wood […]

-

The Guide of importing WPC Decking or WPC wall cladding from China

WPC decking or WPC Wall cladding is currently a trending product among importers. As in the case of other building materials, there are strict regulations in place – regulations which far from all Chinese manufacturers are compliant with. Besides, there is a wide product quality disparity between different suppliers. Product specifications WPC Means Wood-plastic composite. Basically, the material is made of wood flour and plastic, such as PVC (Polyvinyl chloride), HDPE (High-density polyethylene) and PP (Polypropylene). Wood flour and HDPE is the most common material composition among Chinese manufacturers. The most formulas for WPC decking or wall cladding is : 60% Wood/ Bamboo Power+ 30% PVC/PE/PP+ 10% additives Chinese Manufacturers provide machinery, labor and manufacture products according to the buyer’s product specifications. A WPC decking product specification shall at a minimum contain the following: Size (Such as 140*25 mm, 146X22mm) Length (Such as 2.2 m or 5.4 m) Color (Such as Black, Gray, Olive Green, Red Wood, Coffee, Wood) Material components (Such as 60% wood power + 30% HDPE +10% chemical additives) Surface (Such as Smooth, Brushed, Scratched, Grain or Sanded) Lifetime (Such as 25 years) Usage (Such as Outdoor or Indoor) Anti-slip (Yes / No) Anti-UV (Yes / No) Waterproof (Yes / […]

-

Five ways from Hanming for How to clean the WPC decking ?

How to clean the WPC decking ?( Five Ways for different situations) With the plastic wood floor is recognized, many private housing began to choose plastic wood flooring. Many people don’t know how to clean up plastic flooring when there are various stains on their surfaces. Green wood manufacturers through the summary, collate out five ways to share with everyone. Method 1. If there is dust or dirt on the plywood floor, clean it with a broom or brush, then rinse with cold water. Method 2. If there are grease stains on the plastic wood floor, clean with deoiling detergent, and then rinse with heat. Method 3. If the plastic wood floor is marked with colored pens or other colors, clean with hot soapy water and bleach, but this method does not completely remove it. Therefore, do not use oil-colored pens or other products on plastic floors. Method 4. If the plastic wood floor remains dirt, rust stains, using oxalic acid or phosphoric acid containing cleaning products for cleaning, but this method is only to reduce the stains, it is difficult to remove them completely. Method 5. If the plywood floor is sprinkled with juice and wine, mix the bleach in […]

-

Plastic wood tray | WPC pallet prospect from China

According to the statistics of China Federation of Logistics and Purchasing, there are about 100 million pallets in China, and they are increasing at an annual rate of about 10, 000. With the application of this technology and the acceleration of market recognition, the market share of plastic wood pallet is expected to be reached within this year. Considering that the market share has certain volatility and uncertainty due to various unpredictable factors, the most conservative situation is calculated according to the market share of this product. The size of pallet used by different products is different. At present, the price of wooden pallets on the Chinese market ranges from tens of yuan to thousands of yuan. According to the minimum price of wood pallet and the price of plastic wood pallet, the direct economic output value can be up to 100 million yuan per year. According to the situation abroad, the profit margin of this product is at least above. Therefore, after normal production, plastic wood tray net profit can reach more than 100 million yuan. Therefore, the economic benefit of plastic wood tray is very great. China Plastic wood tray is a new type of tray which is […]