Our company is comprised of a team of professionals with over twenty years of experience in the design, manufacturing, and commissioning of plastic extrusion molds.The company boasts specialized production capabilities centered on R&D, design, and manufacturing, providing comprehensive services for large-scale and diverse plastic engineering projects.We have produced hundreds of molds for large and medium-sized profile manufacturers both domestically and internationally. We also develop profile molds, foaming molds, PE-WPC, foamed WPC, co-extrusion molds, and WPC extrusion molds. Our reliable technical support and superior product quality have earned the trust of numerous customers. With comprehensive after-sales service and a customer-centric approach, we welcome more profile manufacturers, both domestically and internationally, to join us in pioneering the industry.

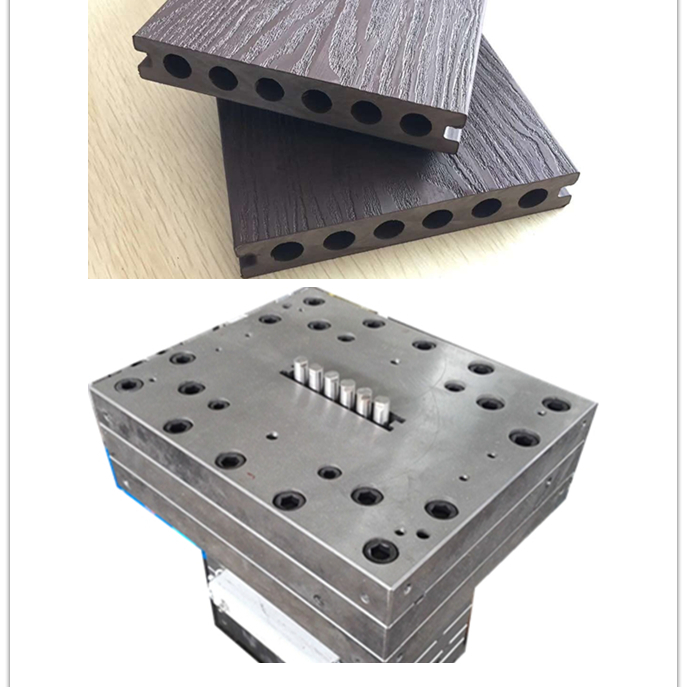

| Name | WPC Deck Tile System Extrusion Mould |

| Size | Various types |

| Mould material | 3Cr17, 3Cr17MoNiV, DIN1.2316 or as per your request |

| Mould cavity | 1 or multi-cavity |

| Mould composition | Die head, aluminum heating bands, calibrators and water tank |

| Feature | Selectable co-extrusion of different raw materials: PVC, PP, PE, ABS

Selectable technology: low-foaming, high-foaming & substance co-extrusion Stable discharging, high efficiency, superior quality |

| Test | Mould will be tested to get the satisfy sample before deliver |

| Sample | Sample will be arranged by express courier for customer approval |

| Service | Provide complete set of production process and technology transfer service |

| Lead time | 35-40 days |

| Package | Poly wood case for exporting, each mould will be cleaned before packing. |

| Quality assurance | ISO9001 |

Extrusion dies rely on the principle of continuous extrusion molding and are particularly suitable for producing long or hollow profile products, such as architectural decorative lines and outdoor flooring. Their stable temperature control system and adjustable die design make the material flow more uniform, and the finished product has excellent surface finish and dimensional stability.

Mould Produce Process:

Packaging of the WPC decking Moulds

In the field of wood-plastic molds, quality is the foundation of a company’s success. We begin with raw material selection. Every sheet used in mold production undergoes multiple inspection processes to ensure its physical properties and stability meet standards. During production, we utilize high-precision processing equipment and standardized processes, monitored by experienced technicians throughout the process. Key indicators such as dimensional tolerances and surface finish are strictly controlled to prevent defective products from reaching the next stage. Before shipping, finished products undergo performance testing simulating actual operating conditions, covering key parameters such as compressive strength, wear life, and demolding efficiency. Data-driven reports guarantee quality, ensuring that each mold withstands market scrutiny.

|

Name |

PE WPC solid decking profile mould for outdoor flooring |

|

Size |

Various sizes as customer’s request |

|

Variety |

According to customer’s request |

|

Mould Material |

3Cr17, 3Cr17MoNiV, DIN1.2316 or Negotiable |

|

Mould Cavity |

One or Multi-Cavity |

|

Mould Composition |

Die Head, Calibrators and Water Tank |

|

Feature |

High Polished Surface, Stable Discharging, Soft-hard, Surface Layer, Cladding |

|

Test |

Mould will be tested to get the satisfy sample before delivery |

|

Sample |

Sample will be arranged by express for customer approval |

|

Service |

Provide complete set of formulation, technology and perfect after sale service |

|

Lead time |

30-35days |

|

Package & deliver |

Poly wood case for exporting, each mould will be cleaned before packing. |

|

Remark : If you are interesting in mould and plastic prodcuts, welcome you provide us the details of the product material , size , weight ect, better 2D and 3D drawing. |

|