Product Category

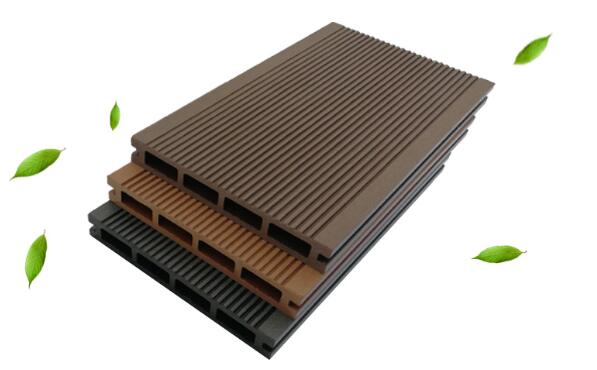

- Composite decking (WPC )

- DIY interlocking decking tiles

- Wall Panel(composite Siding)

- WPC | Composite Fencing

- WPC | Composite Railing

- WPC Bench

- WPC dustbin

- WPC Flower Box

- WPC Pergola|Pavillion

- WPC Table

Contact Us

Salesman Name: Nick ,Jean

Tel:+86-572-6076365

whatsapp:0086 18705825615

wechat:3402182830

Skype:Nickwpc88

Email: Admin@hanmingwpc.com

Add:Huzhou City, Zhejiang, CHINA

Follow Us:

- Outdoor WPC decking

Hanming WPC Pergola

WPC Fence

Hanming WPC dustbin

Pontoon composite wood

Terrace WPC decking

Archive for September, 2018

-

Manufacturing Technology of Wood and plastic products in China

Wood-plastic composites (WPCs) are composite materials made of wood fiber/wood flour and thermoplastic(s) (includes PE, PP, PVC, PLA etc.). In addition to wood fiber and plastic, WPCs can even contain different ligno-cellulosic and/or inorganic filler materials. WPCs area unit a set of a bigger class of materials known as natural fibre plastic composites (NFPCs), which can contain no cellulose-based fiber fillers like pulp fibers, peanut hulls, bamboo, straw, digestate, etc. Composite decking may be a semisynthetic building product that has AN approximate equal mixture ofrecycled wood fibers and recycled plastic. as a result of composite decking product area unit thus sturdyand run-resistant to rot, they need a way longer lifetime than wood decks. they are doing not need the staining, sanding, sealing, and board replacement that return in conjunction with wood decks. even if they need a lot of initial investment, a composite deck over makes up for that initial value over the lifetime of the deck. With the numerous blessings of composite decking, like lower maintenance and being immune to mildewand insects, composite decking has been deemed one amongst the most durable decking productson the market nowadays. additionally to those advantages, new capped composite decking is additionally stain and fade resistant, which implies it’s easier to scrub and has terribly high color retention. Maintaining your composite deck requires semi-annual cleaning; simply a fast spray of the hose with a gentle house cleaner can do the trick. Capped composite decking is sealed and is less complicated to scrub if mildew and mildew type on the surface. Since there area unit exposed wood fibers in uncrowned composite decking planks, it may be vulnerable to mildew growth rather like any outside surface. However, improvement your deck sporadically will facilitate keep mildew trapped. Wood-plastic equipment experts introduce the existing technology, wood plastic products including several forms of molding: extrusion molding, calender molding, injection molding, pressing molding […]

-

What is wood plastic ? | where can wood plastic be applied ?

As early as a few decades ago, the United States began the research and extrusion of wood-plastic composites, but due to the immature processing technology, compared with plastics and pure wood products, there are many performance defects, wood plastic composites have not been rapid development. With the breakthrough of industrial technology level, the new processing technology has greatly improved the performance of wood Plastic composite materials, and the market of wood-plastic products has opened rapidly with the breakthrough of industrial technology level. The new processing technology has greatly improved the performance of wood-plastic composites and opened the market of wood-plastic products rapidly. 1:What is wood plastic ? Wood Plastic Composite (WPC) is a new kind of composite material which is flourishing in recent years at home and abroad. It refers to the use of polyethylene, polypropylene and polyvinyl chloride (PVC), instead of the usual resin adhesive, and more than 35% – 70% of wood flour, rice husk, straw and other waste plant fibers mixed into a new wooden material, and then extruded. Molding, injection molding and other plastic processing technology, the production of plates or profiles. At present, mainly used in building materials, furniture, logistics packaging and other industries. It […]

-

How to select a wood plastic WPC pavilion

Pavilion is a landscape in park, villa community,etc,Chic wooden pavilions not only increase beauty, but also give people a better sense of natural and healthy life,But as an outdoor pavilion, year-round weather and rain, the use of inappropriate materials is very easy to age and rot, very beautiful.As a new type of environmental protection material, outdoor wood plastic composite material can be used for 30 years without fading, decay and cracking. The pavilion made of plastic wood material can be called the most perfect combination. Below are some cases of plastic wood pavilions made by manufacturers for your reference. First of all, in the selection of wpc pavilion on the important point is to look at the appearance of the pavilion. The appearance here refers to the details of the workmanship of the pavilion.High-quality pavilions are well made, and whether there is a gap between them.Whether it is a column or guardrail, tables and chairs and other hands can be touched, smooth, there is no place to prick.Not only beautiful, easy to manage and use, but also safe, do not worry about children playing in the wpc pavilion injury. Secondly, on the choice of plastic wood Pavilion, the key point is […]

-

Basic Direction of Development of Co-Extruded WPC deck

According to the international PE plastic wood market, there are two categories of coextrusion and non-coextrusion. From the aspect of covering layer coverage, we can see that PE plastic wood is divided into the following five types: 1. Coating layer 360 degree all-round coating core layer 2. The slot position of the plate is notched, and the coating layer is not completely coated with the core layer. The coating layer can only cover the upper half of the plate, that is, the core layer can only cover 1 / 2 of the core layer. The cladding layer uses the same plastic-wood material as the core layer, which is equivalent to the first generation plastic wood. Core layer without any direct exposure, that is, the first generation of plastic wood. best deck material The first four kinds of wpc have cladding layer, which belongs to co-extruded wpc, and the fifth kind is the simplest first generation plastic wood without any cladding layer. From the application of these five kinds of wpc, we can see the future development direction of co-extruded wpc. Application performance of various plastic wood products: The first generation of plastic-wood applications: the first generation of plastic wood, whose […]

-

WPC decking formula details from Hanming WPC Group

“Plastic wood materials “, also known as” wood plastic composites “, as the name implies, can be understood that mainly use plastic (polypropylene -PP, polyethylene -PE, polyethylene-PVC and other recycled waste plastics ) as raw materials, by adding wood powder, rice husk, straw and other waste plant fiber materials, and then through extrusion, molding, injection molding and other process, produced to sheet or profile. Mainly used in building materials,outdoor flooring, logistics packaging and other industries. The plastic and wood powder are mixed in a certain proportion and then hot extruded, which is called extruded wood plastic composite board. WPC composite decking formula from Hanming; 35% environmental plastic materials(Grade A HDPE or new PP) 55% natural fiber (wood powder, bamboo powder, etc) 10% chemical additives. (Anti-UV agent, Anti-oxidation agent, stabilizers, colorants, anti fungus agent, coupling agent, reinforcing agent, lubricants.) 1.With high density,durable,high strength and elegant looking 2.Anti-corrosion,anti-crack,anti-deformation 3.Water proof,Easy to maintainance and clean 4. Environmental friendly, low carbon,100% recyclable. 5. Easy installation, auto-locking 6. Temperature resistance, suitable from -29°C to +51°C 7. Long-lasting to use (10 years warranty) 8. With wood scent, very natural feel WPC decking board test report TEST ITEM(wpc decking) STANDARD RESULT DROP TEST No Flaw, No Crack ,No Fracture Qualified SHORE HARDNESS, HD ≥ 45 99 Nail-Holding Power, N […]