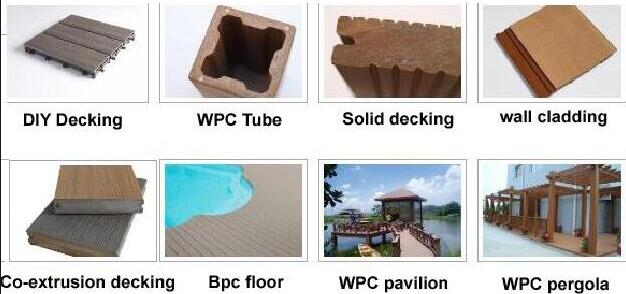

Product Category

- Composite decking (WPC )

- DIY interlocking decking tiles

- Wall Panel(composite Siding)

- WPC | Composite Fencing

- WPC | Composite Railing

- WPC Bench

- WPC dustbin

- WPC Flower Box

- WPC Pergola|Pavillion

- WPC Table

Contact Us

Salesman Name: Nick ,Jean,wendy,Alex

Tel:+86-572-6725956

whatsapp:0086 18705825615

wechat:3402182830

Skype:Nickwpc88

Email: Admin@hanmingwpc.com

Add:Huzhou City, Zhejiang, CHINA

Follow Us:

- Outdoor WPC decking

Hanming WPC Pergola

Garden WPC Decking

WPC Fence

Stainless steel park bench

WPC Flower BOX

Hanming WPC dustbin

Pontoon composite wood

Terrace WPC decking

Assemble flower box

Pergola made of WPC

Outdoor WPC Signage

News

-

How to select a wood plastic WPC pavilion

Pavilion is a landscape in park, villa community,etc,Chic wooden pavilions not only increase beauty, but also give people a better sense of natural and healthy life,But as an outdoor pavilion, year-round weather and rain, the use of inappropriate materials is very easy to age and rot, very beautiful.As a new type of environmental protection material, outdoor wood plastic composite material can be used for 30 years without fading, decay and cracking. The pavilion made of plastic wood material can be called the most perfect combination. Below are some cases of plastic wood pavilions made by manufacturers for your reference. First of all, in the selection of wpc pavilion on the important point is to look at the appearance of the pavilion. The appearance here refers to the details of the workmanship of the pavilion.High-quality pavilions are well made, and whether there is a gap between them.Whether it is a column or guardrail, tables and chairs and other hands can be touched, smooth, there is no place to prick.Not only beautiful, easy to manage and use, but also safe, do not worry about children playing in the wpc pavilion injury. Secondly, on the choice of plastic wood Pavilion, the key point is […]

-

Basic Direction of Development of Co-Extruded WPC deck

Co-extruded wood-plastic composite (WPC) decks have gained popularity in recent years due to their durability and low maintenance requirements. These decks are designed to withstand harsh weather conditions, resist fading and scratching, and require minimal upkeep compared to traditional wooden decks. The basic direction of development for co-extruded WPC decks includes enhancing their color options, improving their resistance to moisture and mold, and exploring sustainable materials for their production. Co-extruded WPC decking has excellent anti-corrosion and moisture-proof properties,It can effectively resist humid environments and water penetration, and it is very suitable for installation in outdoor areas. WPC co-extruded decking has good mechanical properties, anti-aging, good dimensional stability, and is not easy to crack. Its environmental performance is also very outstanding. The raw materials used in its production are mostly renewable resources, without formaldehyde release, and harmless to human health. This type of WPC decking also has excellent wear resistance, and the wear-resistant layer covering the surface can withstand friction on the soles of the feet, extending its service life. best deck material This kind of co-extrusion wpc decking has a unique material composition, which not only retains the natural texture and warmth of wood, but also incorporates the water resistance […]

-

WPC decking formula details from Hanming WPC Group

“Plastic wood materials “, also known as” wood plastic composites “, as the name implies, can be understood that mainly use plastic (polypropylene -PP, polyethylene -PE, polyethylene-PVC and other recycled waste plastics ) as raw materials, by adding wood powder, rice husk, straw and other waste plant fiber materials, and then through extrusion, molding, injection molding and other process, produced to sheet or profile. Mainly used in building materials,outdoor flooring, logistics packaging and other industries. The plastic and wood powder are mixed in a certain proportion and then hot extruded, which is called extruded wood plastic composite board. WPC composite decking formula from Hanming; 35% environmental plastic materials(Grade A HDPE or new PP) 55% natural fiber (wood powder, bamboo powder, etc) 10% chemical additives. (Anti-UV agent, Anti-oxidation agent, stabilizers, colorants, anti fungus agent, coupling agent, reinforcing agent, lubricants.) 1.With high density,durable,high strength and elegant looking 2.Anti-corrosion,anti-crack,anti-deformation 3.Water proof,Easy to maintainance and clean 4. Environmental friendly, low carbon,100% recyclable. 5. Easy installation, auto-locking 6. Temperature resistance, suitable from -29°C to +51°C 7. Long-lasting to use (10 years warranty) 8. With wood scent, very natural feel WPC decking board test report TEST ITEM(wpc decking) STANDARD RESULT DROP TEST No Flaw, No Crack ,No Fracture Qualified SHORE HARDNESS, HD ≥ 45 99 Nail-Holding Power, N […]

-

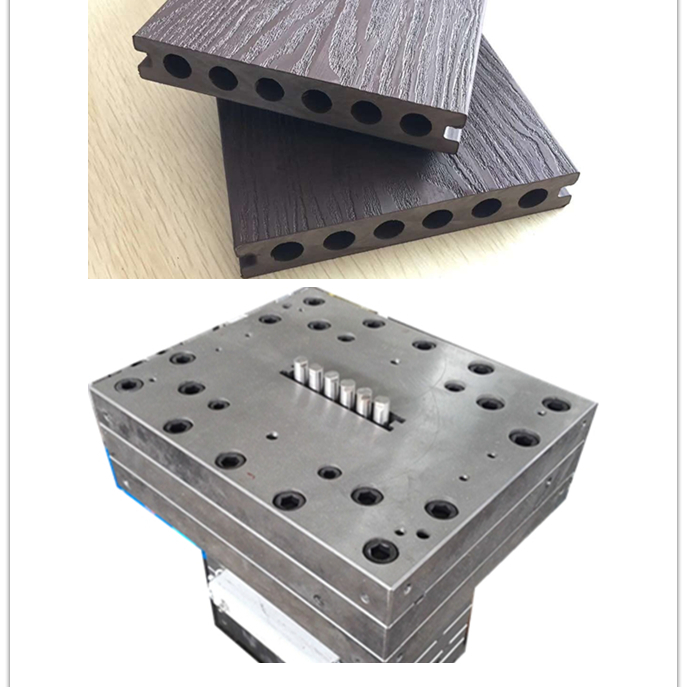

china wpc outdoor flooring moulds supplier | wpc Decking mould Factory in China

Our company is comprised of a team of professionals with over twenty years of experience in the design, manufacturing, and commissioning of plastic extrusion molds.The company boasts specialized production capabilities centered on R&D, design, and manufacturing, providing comprehensive services for large-scale and diverse plastic engineering projects.We have produced hundreds of molds for large and medium-sized profile manufacturers both domestically and internationally. We also develop profile molds, foaming molds, PE-WPC, foamed WPC, co-extrusion molds, and WPC extrusion molds. Our reliable technical support and superior product quality have earned the trust of numerous customers. With comprehensive after-sales service and a customer-centric approach, we welcome more profile manufacturers, both domestically and internationally, to join us in pioneering the industry. Name WPC Deck Tile System Extrusion Mould Size Various types Mould material 3Cr17, 3Cr17MoNiV, DIN1.2316 or as per your request Mould cavity 1 or multi-cavity Mould composition Die head, aluminum heating bands, calibrators and water tank Feature Selectable co-extrusion of different raw materials: PVC, PP, PE, ABS Selectable technology: low-foaming, high-foaming & substance co-extrusion Stable discharging, high efficiency, superior quality Test Mould will be tested to get the satisfy sample before deliver Sample Sample will be arranged by express courier for customer approval […]

-

The suggestion for how to choose WPC decking properly

Wood plastic outdoor flooring is a kind of flooring with rapid market increment in recent years. Because of its peculiar texture luster and stable performance, it has been favored by many consumers, but the real understanding of wood-plastic flooring is still not much. Just say, when we buy, the right way to choose and buy, do you know? 1, to see the side of wood-plastic floor: good quality wpc decking side of the smooth, glossy shiny, a sense of oil-run, no small cracks. Poor quality of wood-plastic floor side of the rough, shiny dim, no oil-run feeling, and some poor elongation due to PE cracks. 2, look at the front of composite decking: good quality wood-plastic floor front smooth, glossy shiny, wood powder particles small and uniform size. Poor quality wood-plastic floor front rough, shiny dim, wood powder particles larger, different sizes, uneven distribution. Two kinds of floor put together, the difference is obvious. 3, look at the wood-plastic floor section: good quality wood-plastic floor section texture tight, shiny glossy, small and uniform distribution of wood powder particles. Poor quality of the wood-plastic floor section texture loose, shiny, wood powder particles larger, different sizes, uneven distribution, and obviously see the wood […]