Let’s understand the basic characteristics of outdoor WPC decking . Outdoor WPC is a composite material that uses high-density polyethylene (HDPE) or polypropylene (PP) and other polymer materials as the base material and is processed through special processes. It has the following salient features: 1.Water resistance: Because its base material has excellent waterproof properties, outdoor wpc Deck can maintain stable physical properties even when exposed to rain and moisture for a long time. 2.Anti-corrosion: Compared with wood, outdoor wpc decking is more resistant to corrosion and will not be damaged by moisture or insects, extending its service life. 3.Easy to maintain: Because its surface is smooth and does not easily absorb dirt, cleaning and maintenance are relatively simple, just rinse with clean water.

We need to know that the material for the production of wood plastic composite decking can be called “ecological wood “, what is called” ecological wood “, because its production process does not contain formaldehyde, nor any material harmful to the human body, both safe and environmentally friendly a composite material. So in the choice of decoration materials now more consumers tend to plastic wood floor. The WPC floor is made of wood and other raw materials into powder and plastic, and then pressed into a model under high temperature conditions, in the production of the product is not required to use adhesive, so it does not contain any harmful substances; but the traditional floor is not the same, like solid wood or composite ground Formaldehyde is a harmful substance to the human body, so the plastic wood floor should be promoted more than the traditional floor.

Outdoor wood polymer composite

Wood plastic composite decking has gained immense popularity in China due to its numerous advantages over traditional wood decking. These decking materials are a combination of wood fibers and plastic, offering a durable, low-maintenance, and eco-friendly alternative for outdoor flooring. In China, where environmental concerns are on the rise, the use of wood plastic composite decking aligns well with the sustainable development goals of the country.

The application of wood plastic composite decking in China extends beyond residential properties to commercial and public spaces. Its versatility, attractive aesthetic, and long lifespan make it a preferred choice for decking projects in various settings. Additionally, the availability of a wide range of colors and finishes allows for customization to suit different design preferences and architectural styles prevalent in China.

As the demand for sustainable building materials continues to grow in China, the market for wood plastic composite decking is poised for further expansion. With advancements in technology and manufacturing processes, these decking materials are expected to evolve to meet the evolving needs of the Chinese market.

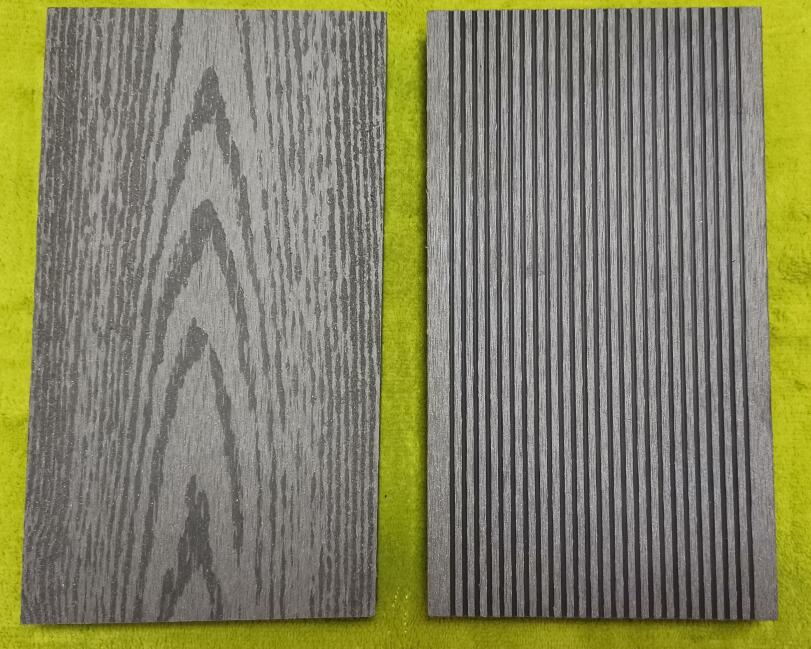

wood plastic composite decking in the performance of wood and plastic dual advantages, appearance and wood texture realistic natural and good material stability, not easy to crack, deformation, warping. Anti-aging products, anti-corrosion, anti-insect ants, water absorption is small. Rich in color, as easy as wood processing, whether cutting, planing, nail, drill are very simple. Furthermore, wood-plastic outdoor flooring is produced by high temperature melting and high pressure extrusion; therefore, wood-plastic flooring products have a more compact structure. As high as 1.3 g/cm3, the density of wood-plastic floors is about three times that of conventional wood, wood-plastic floors also have better anti-mildew, anti-corrosion, anti-moisture, insect control effect, but also has more wear resistance, stain resistance and better aging resistance.

Changxing Hanming Technology Co.,LTD

Contact Person: JEAN

Email: Jean@hanmingwpc.com