140X40mm Solid WPC decking for waterborne platform

Price:22Usd/sqm-36usd/sqm

Brand: Hanming WPC

Composition:55% Bamboo Powder/Wood Fiber, 35% HDPE, 10% Additives

Color:Black, Cedar, Coffee, Dark Grey, Silver Grey, Yellow, Red and Wood, or customized

Size:140X40mm, 150X25mm, 145X30mm, 140X25mm, or customized

Length:2200mm, 2900mm, or customized

If you are looking to enhance your outdoor space with durable and eco-friendly decking, consider the benefits of 140X40mm Solid WPC Decking from a reputable factory in China. With its sturdy construction and low maintenance requirements, this decking option offers a cost-effective solution for creating a stylish and sustainable outdoor living area. Whether you are renovating your backyard or designing a new deck for your home, investing in high-quality WPC decking can provide long-lasting beauty and functionality. Explore the various design options available and transform your outdoor space into a welcoming retreat for relaxation and entertainment.

140x40mm is a size of WPC, 140mm is the width, 40mm is the thickness, the length can generally use 2.2m, 2.9m, 3m, 4m, 140X40mm solid board is used more, the solid board of this thickness can bear considerable weight, Therefore, it can be used on floors with large traffic, parking lots, and bridge flooring.In China, some waterborne platform projects also use this specification.140X40mm uses a lot of Raw materials, so the price is generally more than 30 US dollars per square meter. For outdoor projects, using this specification requires sufficient budget.

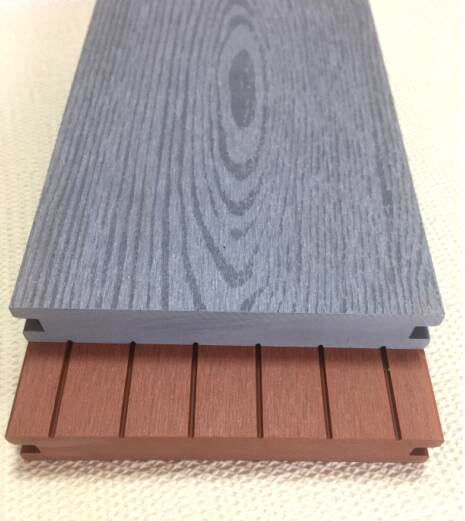

This wood plastic solid decking floor, also known as WPC solid flooring , It is used for outdoor projects, Our 140X40mm Solid size, Weight : 7.07KGS Per meter, One side with many grooves, and another side is Smooth.

、

、

140x40mm Solid waterborne platform Wood Plastic floor

When looking for durable and stylish decking options, considering the advantages of 140X40mm Solid WPC decking from China can be a great choice. With its high-quality wood-plastic composite material, this type of decking offers excellent benefits such as low maintenance, resistance to rotting and insects, and a long lifespan. Additionally, the size of 140X40mm provides a sturdy and stable base for outdoor areas, making it ideal for various applications. Stay tuned for more insights on why choosing this type of decking can elevate your outdoor space to the next level.

if u need 140X40mm WPC hollow Decking , we aslo can Provide u .

\

\

140X40mm Hollow waterborne platform Wood Plastic floor

Specifications: 140 x 40mm, solid, One side without grooves, the surface can be polished and embossed with wood grain;Application: road plank, open-air leisure, sports venues, near water landscapes and other places ;

WPC Solid Joist for wood plastic composite deck

The wood Plastic floor is Produced by extruder.

Eco wood is a floor made of wood-plastic composite material. It is mostly used in gardens, villas and outdoors.

Waterborne platforms offer architects and designers a unique canvas to showcase their creativity and push the boundaries of architectural design. With 140X40mm Solid WPC decking, these visions can become a reality.

The versatility of this decking material allows for innovative designs that seamlessly integrate with the surrounding environment. Whether it’s a floating platform that appears to blend into the water or a multi-level structure that provides panoramic views, architects can create captivating spaces that leave a lasting impression on visitors.

Moreover, the use of 140X40mm Solid WPC decking opens up opportunities for incorporating other sustainable features into waterborne platforms. From solar panels to rainwater harvesting systems, these platforms can become showcases of eco-friendly technologies, further enhancing their appeal.

The Price of 140X40mm Solid composite decking is about 44 USD Per sqm, Hanming WPC has 3 Molds for this Size, and 8 Colors in options, 140X40mm Solid board has stronger bearing capacity than hollow items, At the same time, the weight of the board itself is relatively heavy, One 20′ Container can only loading about 500Square meters, The surface of solid wood plastic floor usually has wood Texture or Small grooves, The natural wooden feeling is very popular by the garden scenic spot, garden hotel, villa club and other project parties

Case Studies: Success Stories of WPC Decking Implementation

To truly understand the impact of 140X40mm Solid WPC decking on waterfront designs, let’s explore some real-life case studies:

1. The Marina Promenade: In a bustling waterfront city, a marina promenade was transformed using 140X40mm Solid WPC decking. The result was a stunning walkway that not only provided a safe and durable surface but also enhanced the overall aesthetic appeal of the area. Visitors now enjoy leisurely strolls along the waterfront, surrounded by breathtaking views.

2. Floating Restaurant: A visionary architect designed a floating restaurant using 140X40mm Solid WPC decking for both the exterior deck and interior flooring. This choice not only added an element of luxury to the dining experience but also ensured that the restaurant could withstand constant exposure to water without compromising on style or comfort.

These case studies demonstrate how 140X40mm Solid WPC decking has been successfully implemented in real-world projects, showcasing its versatility and ability to elevate waterfront designs.

If u are interested in our 140X40mm Wood plastic Decking, Pls contact with us by email: