No crack UK WPC outdoor decking| UK WPC Deck board from China

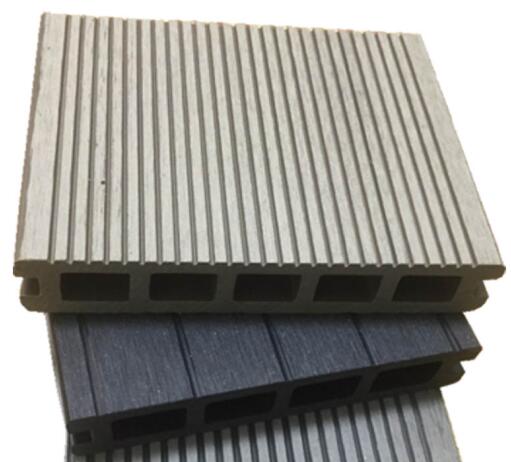

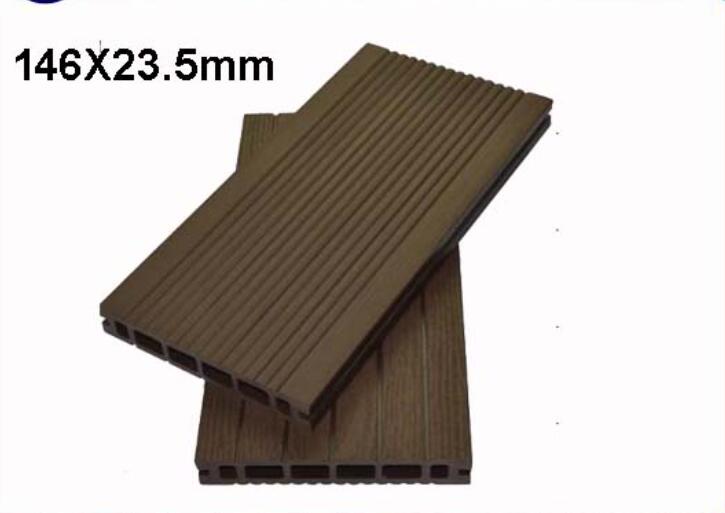

Color: Black, Brown, Dark Brown, Red, Green, Yellow

Price: 16usd/sqm–22usd/sqm

Material component: 45% PE + 50% Wood Fiber + 5% special additives

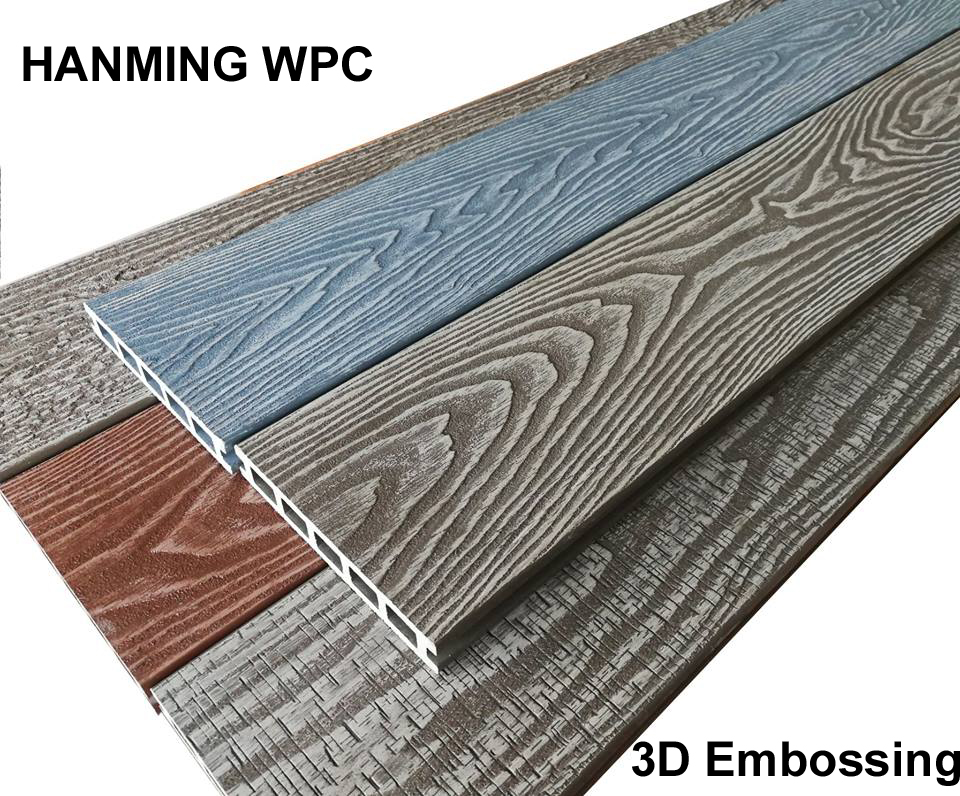

Surface: Smooth, Brushed, Grooved, Grain optional

Techniques: Wood-Plastic Composite

Function: Waterproof, Anti-UV, Rot-proof

Warranty: 15 years

Certificate: CE, SGS, ISO

Package: PE Film + WPC Pallet (length of 0-2.2m) or Wood Pallet (length>2.2m)

The range of use: Garden, Lawn, Balcony, Corridor, Garage, Pool & SPA Surrounds, Boardwalk, Playground

In the UK’s humid, rainy climate with wide temperature swings, WPC has rapidly gained popularity thanks to its excellent moisture and corrosion resistance. From home gardens to municipal trails, from seaside piers to rooftop terraces, it can be found everywhere. Compared to natural wood, which is prone to cracking and deformation, WPC achieves a balance of rigidity and toughness through a scientific formulation. A special surface treatment allows the natural wood texture to be retained, while also offering advantages such as resistance to termite infestation and resistance to UV aging.

UK WPC outdoor decking Physical characteristics: High strength, high hardness, slip resistance, abrasion resistance, no crack, no insects, small water absorption, anti-aging, corrosion-resistant, anti-static and anti-UV, insulation, thermal insulation, fire-retardant, resistant to 75 ℃~ -40 ℃ temperature, lifetime can be 3 times of that of ordinary wood materials. UK WPC outdoor decking

UK composite decking installation is very convenient and quick, according to the specific needs of their own space processing, decorative effect is good, corrosion-resistant, easy to clean.

composite Lumber in UK with wood Texture

UK wood plastic composite decking have a natural appearance of wood, texture. No wood knots, no cracks, warping, deformation. Plasticity, can achieve personalized shape, the product can be made into a variety of colors, the surface without the need for a second leaching paint can also long-term security does not fade. Renewable, non-toxic substances, dangerous chemical composition, preservatives, etc., no formaldehyde, benzene and other harmful substances release, will not cause air pollution and environmental pollution, 100% recycling, but also biodegradable.

Why do you want to leave a gap when installing plastic wood?

Many customers are not particularly aware of this, in view of this situation, intended to come with you to explore the reasons for this one, if you have some other ideas, may wish to communicate with us.

In the installation of plastic wood when the need to leave the gap, the purpose of doing so mainly for the following factors: 1, drainage; 2, a slight thermal expansion and contraction; 3, cleaning;

Although the plastic wood will not because of the wet and dry And expansion and contraction occurs, but will be based on changes in temperature and a certain degree of expansion and contraction, so in the edge and the head to the head to leave the gap is necessary, especially in the winter when installed.

WPC outdoor decking flooring

A. Good social economy and sustainable development, especially suitable for the policy of “forest protection”;

B. Durable, long life, similar to wooden appearance, higher than plastic hardness;

C. Have excellent physical properties, better than wood dimensional stability, won’t produce cracks, warping, no wood knots, twill, join the colorant, coated or complex alloy surface can be made into various colorful products;

D. The processability of thermoplastic plastic is easy to form, and can be processed with general plastic processing equipment or slightly modified. The new investment of processing equipment is small and easy to promote the application;

E. The secondary processing of similar timber, can be cut, glued, and fixed with nails or bolts;

F. For decoration and decoration, can be painted and beautified. The product specifications can be adjusted according to the requirements of users.

G. Not afraid of moth, aging, corrosion resistance, small water absorption, no moisture absorption deformation;

H. Can reuse and recycle, biodegradable, protect the environment;

I. Conducive to environmental protection, usable waste wood, crop fiber and waste plastic materials;

J. Abundant resources, low cost, low cost of use.

In the residential courtyard sector, UK WPC decking has become an ideal choice due to its rich patterns and textures and flexible size adaptability. For example, in a detached villa project in the suburbs of London, the owner chose 140X25mm oak-colored WPC decking, which not only retained the visual texture of natural wood but also avoided cracking and deformation problems.

.

.

Building Materials Exhibition in Birmingham, UK,A lot of Chinese manufacturers are also there to show off some of the new WPC decking,like Capped compoisite decking, wpc fencing, 3D embossing decking,Railing, wall cladding,etc.

In the UK, the use of wpc has been very common. You can see them in parks, gardens, terraces, balconies, and even walking paths along the beach. This is mainly due to the high weather resistance and corrosion resistance of WPC decking, which can withstand the changeable weather conditions in the UK.

In terms of experience, consumer feedback in the UK has been very good. They said that the color and texture of the wood-plastic floor are natural, giving people a warm and comfortable feeling. Moreover, it is very easy to install and maintain. All it takes is regular cleaning and occasional sanding to keep the floor looking good.

If you are interested in our WPC Products, pls send inquiry to us or by email.

Our Email address is : admin@hanmingwpc.com

[contact-form-7 404 "Not Found"]